We are a leading manufacturers and exporters of Reactor, Chemical Reactor, Pharmaceutical reactor in India.

Reactor, unlike mixing tanks, are totally sealed from the atmosphere. Mixing tanks are designed to disperse two or more chemicals together. Reactor on the other hand, allow the chemicals inside to go through a reaction phase which ultimately produces new and different chemical properties.

Tri-shaft mixing tank usually consists of 3 agitators: wall scraper,high speed mixing and low speed mixing.The low speed mixing can be frame or anchor type with scrapers.It rotates to mix materials and to scrape materials attached on the container wall at the same time. High speed mixing ensures to mix and disperse materials quickly and efficiently. No dead corners and residuals. Easy cleaning and efficient mixture.

Send Enquiry

Pharmaceutical chemical reactor is for making base liquids before final reaction. Usually it has an agitator and a jacket outside for input conduction oil. The oil is heated by electric rods. There are oil inlet, outlet, overflow port, vent port, electric rods port, and temperature detection port on the jacket.

Send Enquiry

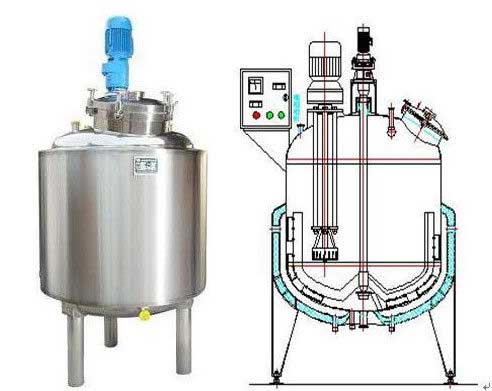

Electric heating mixing tank is a container for mixing, dispersing and reaction of different materials in chemical production, and widely used in chemical, food, pharmaceuticals, resin, coating, paint, ink industry production. It can be either dished end type or flat lid type, with level gauges, temperature detectors and display device, and can open manhole, sight glass, feeding inlet, discharging outlet and spare openings. For different production process and reaction materials, we will have different designs and configurations, such as its shape, overall size, sanitary requirement, seal effect, with condenser, heat exchanger, pressure sensor, temperature sensor and load cell. Various agitators and discharging modes for option.

Send Enquiry

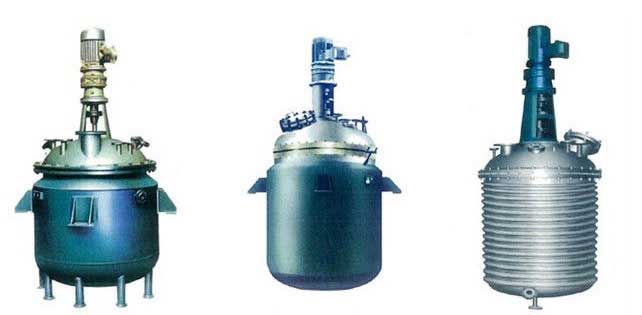

Reactor with agitator has a jacket outside for input conduction oil. The oil is heated by electric rods. There are oil inlet, outlet, overflow port, vent port, electric rods port, and temperature detection port on the jacket.

Send Enquiry

Reactor with coil heating is a container for mixing, dispersing and reaction of different materials in chemical production, and widely used in chemical, food, pharmaceuticals, resin, coating, paint, ink industry production. It can be either dished end type or flat lid type, with level gauges, temperature detectors and display device, and can open manhole, sight glass, feeding inlet, discharging outlet and spare openings. For different production process and reaction materials, we will have different designs and configurations, such as its shape, overall size, sanitary requirement, seal effect, with condenser, heat exchanger, pressure sensor, temperature sensor and load cell. Various agitators and discharging modes for option.

Send Enquiry

Electric heating reactor has a jacket outside for input conduction oil. The oil is heated by electric rods. There are oil inlet, outlet, overflow port, vent port, electric rods port, and temperature detection port on the jacket.

Send Enquiry

Stainless steel vessel is a container with an agitator for mixing, dispersing and reaction of different materials in chemical production. It is widely used in chemical, food, pharmaceuticals, resin, coating, paint, printing ink industry. It can be either dished end type or flat lid type, with level gauges, temperature detectors and display device. Usually, it has manhole, sight glass, feeding inlet, discharging outlet and spare openings. For different production process and reaction materials, we will have different designs and configurations, mainly displayed on its shape, overall size, sanitary requirement, seal effect, with condenser, heat exchanger, pressure sensor, temperature sensor and load cell. Various agitators and discharging modes for option.

Send Enquiry

Strong dispersion mixer is used for high speed dispersion, mix of advanced equipment.Working volume from 5 l to 3000 l, gantry and single arm type structure, is equipped with hydraulic lift to facilitate material cylinder movement and discharging and cleaning;Mixing form by double high-speed dispersion (speed of 0-1500 RPM) and low-speed e type or single pole type scraper scrape side (of 0-63 RPM).Unique mechanical seal and positioning device, the operation is simple, convenient, favored by customers.Strong dispersion mixer is used for powder, liquid, liquid - liquid material dispersion and mixing, strong dispersion machine is widely applied in organic silicone sealant, polyurethane sealant, mold, printing ink, rubber, coating, toothpaste electrode blade material, the production of high viscosity glue, etc.

Send Enquiry

Jacketed reactor is mainly composed of stirring container (including tanks and jacket), stirring device, gear, shaft sealing device, bearing, manhole, process of taking over and some accessories.Mixing device is composed of stirrer and stirring shaft, form by the process design, usually with anchor, pulp, worm gear, pusher, or frame.Set of drive device, transmission device is mainly composed of motor, reducer, coupling and the shaft, etc;Jacketed reaction kettle opening quantity, specifications or other requirements can be designed according to user requirements and production. Heat conduction oil circulation heating reaction kettle mainly by coil within the jacketed heat conduction oil circulating heating or cooling.

Send Enquiry

Electric heating reactor is composed of reactor body, cover, stirrer, electric heating clamp tube, supprting and transmission device, shaft sealling device, overflow tank, and equipmented with electric heating rods, temperature measurements as well as measurements pressure meter. Sirring forms have anchor type, pulp type, turbine type, pushing type and frame type. Supporting seat have suspension type or supporting type two kinds.

Send Enquiry

Jacketed reactor is mainly composed of stirring container(including tanks and jacket), stirring device, tranmission device, shaft seal device, supporter, manhole, connector pipe and so on some accessories. Mixing equipment is compose of stirrer and stirring shaft, its stirring forms is usually up to process design, such as anchor, pulp, worm gear, push type and frame type. Transmission device is setted up for driving stirring device, mainly consist of motor, reducer, coupling and transmission shaft,etc. Jacketed reactor design and produce for opening hole quantity, specification or other requirements according to customer's requirements.

Send Enquiry

Electric heating reaction vessel consists of vessel body, vessel, mixer, electric heating oil pipe, bearing and gear, shaft sealing device, overflow tank, etc, and is equipped with electric heating rod, temperature and pressure gauge.Mixing form include: anchor, pulp, turbine, promote or frame.A suspension or supporting type two kinds.Electric heating reaction kettle placed within the jacketed heat conduction oil, and then by the electric heating rod, on the jacket runs into, oil discharge, discharge measurement, emptying, electric heating rods, temperature measurement to take over the hole, etc.Jacketed wall outside welding pedestal pan body bottom feeding mouth open.Material heating temperature: 300 ℃ or less;Material heating time: 30 min ~ 90 min (see process required).Temperature control: adopt electric measuring temperature and temperature controller connection for temperature measurement and control, and can regulate the temperature of a material of high and low.Thermal insulation material: the filling pearl cotton, rock wool, or casting polyurethane foam, keep temperature difference with the outside world, achieve heat preservation effect.Can also according to customer's technical requirements for design, production, processing, etc.

Send Enquiry

Reactor is used to realize the chemical process requirement of cooling and heating, evaporation, low speed of mixed function.The kettle body, kettle cover, jacket, mixer, gear, shaft sealing device, bearing, etc .Its means of heating steam, electric heating, heat conduction oil, in order to meet the acid and high temperature resistance, wear resistance, corrosion resistance of different working conditions, such as process needs.

Send Enquiry

Electric heating reactor has a jacket outside for input conduction oil. The oil is heated by electric rods. There are oil inlet, outlet, overflow port, vent port, electric rods port, and temperature detection port on the jacket.

Send Enquiry

Electric heating reactor has a jacket outside for input conduction oil. The oil is heated by electric rods. There are oil inlet, outlet, overflow port, vent port, electric rods port, and temperature detection port on the jacket.

Send Enquiry

Reaction vessel is a container with an agitator for mixing, dispersing and reaction of different materials in chemical production. It is widely used in chemical, food, pharmaceuticals, resin, coating, paint, printing ink industry. It can be either dished end type or flat lid type, with level gauges, temperature detectors and display device. Usually, it has manhole, sight glass, feeding inlet, discharging outlet and spare openings. For different production process and reaction materials, we will have different designs and configurations, mainly displayed on its shape, overall size, sanitary requirement, seal effect, with condenser, heat exchanger, pressure sensor, temperature sensor and load cell. Various agitators and discharging modes for option.

Send Enquiry

- SS 316 - Reactor with Double Mechnical Seals

- Shell - 25mm

- Working Pressure 30Kg/cm2

- 100% Rediographed of Weld.